Ultra Motion: Actuators Enhancing Autonomy Across Air, Sea, and Space

By Richard Thomas

Ultra Motion’s advanced actuators provide precision control within extreme environments. Their innovative solutions significantly boost reliability, efficiency, and performance in various autonomous applications.

Actuators serve as critical components in unmanned systems, transforming electronic signals into precise mechanical movements vital for functionality such as thrust vector control, landing gear deployment, and surface manipulation in UAVs. In unmanned surface and underwater vehicles, they control rudder motions, hydrofoil adjustments, and payload release. The performance of these actuators is crucial for the accuracy, reliability, and reactivity of autonomous systems, and therefore, the advancement in actuator technology is pivotal for the future of unmanned platforms.

These components must endure extreme conditions, such as intense vibrations in aerospace, high pressure underwater, and sudden changes in temperature. Innovations in actuator design—including non-contact absolute position feedback and dual-redundant motor setups—help improve both performance and reliability. Ultra Motion, based in Long Island, New York, focuses on actuator technology to provide engineering solutions that guarantee accurate, fail-safe operation in autonomous systems.

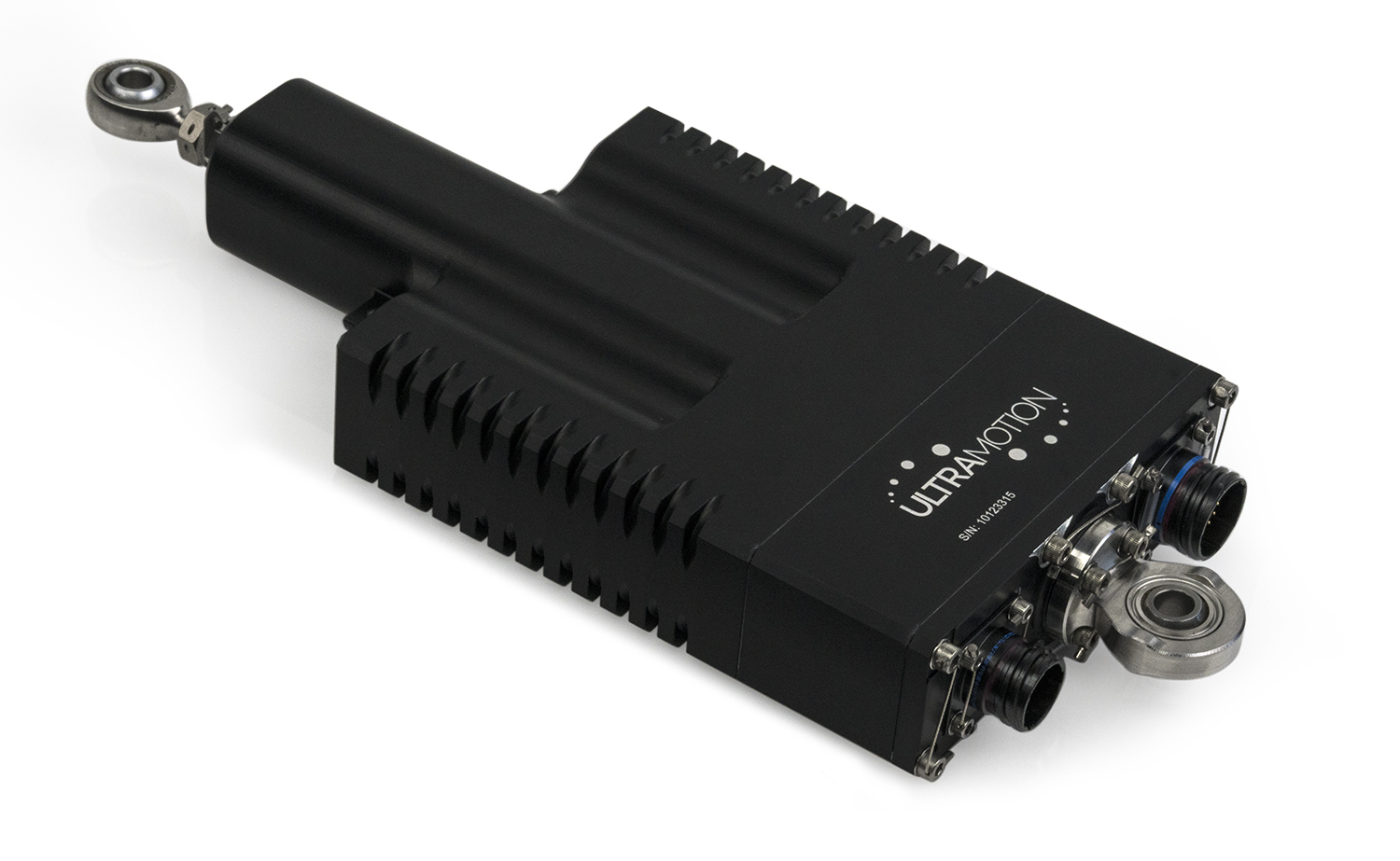

Ultra Motion creates and engineers actuators tailored for demanding scenarios, especially in environments such as subsea applications, aerospace, and space. Their patented Phase Index absolute position feedback technology is at the heart of their products. Each actuator is equipped with built-in control electronics and absolute position feedback, making them exceptionally suited for high-shock environments and submersible systems.

Current Product Portfolio and Unmanned Applications

Ultra Motion’s offerings for unmanned vehicle applications include the AM and AU Servo Cylinders. The AM model is engineered for high shock and vibration resilience, while the AU model is a pressure-compensated, oil-filled actuator meant for submerged contexts. The AM variant is commonly used in thrust vector control for smaller rocket engines, in first-stage applications, and in orbital transfer vehicles. Tom Quartararo, a Mechatronics Engineer at Ultra Motion, mentioned, “Additionally, it’s utilized for manipulating control surfaces in fixed-wing UAVs, managing landing gear, and controlling swashplate and tail rotors in rotorcraft. It also plays a role in uncrewed surface vehicles for rudder and accessory deployment.”

The AU activator, rated for depths exceeding 6,000 meters, is employed in ROVs for dive planes and pin releases for buoys/sensors. Quartararo added, “We’ve recently unveiled the L-Series Servo Actuator, known for zero backlash due to its ground ball screw and duplex angular contact bearing. This design surpasses typical rotary servos, which often have 0.6–1 degree of backlash, allowing for superior control authority, particularly in dynamic drone applications.”

A dual-redundant version of this actuator has been developed, featuring duplicated motors and control electronics alongside triplicated absolute feedback sensors, drawing interest for autonomous rotorcraft applications where considerable oscillatory loads and zero axial backlash considerably enhance reliability.

Ultra Motion’s Phase Index non-contact position sensing elevates actuator efficiency in unmanned systems. Quartararo explained, “In UAVs, absolute position feedback is vital. Other options, like incremental feedback, necessitate homing sequences which are impractical mid-flight. A UAV reliant on incremental feedback would need to recalibrate all control surfaces to zero after a power disruption, which poses significant risks.”

The Phase Index technology delivers absolute position feedback without requiring recalibration, employing non-contact sensing to avoid wear problems, maintaining a compact design to enable triplicated feedback without adding bulk, and operating without batteries, thereby ensuring reliability in extreme conditions.

“Currently, all our actuators incorporate this technology, and it has even been applied in spacecraft that successfully landed on the Moon. Our feedback system guarantees dependable and precise control across various environments—whether in rocket engines, rotorcraft swashplates, or USVs navigating choppy waters,” Quartararo stated.

Engineering for Extreme Conditions

Ultra Motion guarantees its actuators operate effectively amidst extreme conditions through a thorough product development and testing process. Quartararo noted that many of their harsh condition actuators—for example, the AM, L-Series, and T-Series—are results of a lengthy collaboration with SpaceX. This partnership led to the creation of control actuators for the SuperDraco engines in the Crew Dragon’s launch escape system, providing invaluable experience in designing for extreme environments.

Regarding customization to meet unique client requirements, Quartararo explained, “Our aim is to offer commercial off-the-shelf solutions equipped with a wide range of standard options, covering around 90% of potential applications. However, as a nimble and small company, we often adapt mechanical designs, firmware, and electronic components to align with specific customer requirements.”

Customization examples include unique mounting configurations, material changes for specialized purposes, and firmware updates to cater for diverse communication protocols. Customers receive a personalized part number, treating modifications as extensions of the standard product range without being strictly custom builds.

Monitoring Actuator Health & Redundancy

Ultra Motion ensures actuator health monitoring and redundancy through integrated firmware that oversees motor control, communication, and telemetry. Embedded sensors keep track of actuator temperature, bus voltage, and internal humidity, utilizing specially designed desiccants for moisture control over time.

Flight computers can query actuators for telemetry data, enabling informed decision-making, such as monitoring current trends to anticipate potential failures. Quartararo added, “However, actuators do not automatically shut down in case of overheating; we allow users to choose this based on many UAV scenarios where ongoing operation may be preferable to trigger a full system failure.”

Enhancing UAV Efficiency

Actuators contribute to optimizing UAV airframe efficiency, with their high-precision feedback ensuring accurate control surface positioning, which minimizes instability and boosts path tracking. A high-efficiency ball screw design achieves up to 95% efficiency, exceeding traditional gears and hydraulic systems. Transitioning to fully electric actuation negates the need for bulky hydraulic systems, enhancing UAV power efficiency and dependability.

In terms of market areas driving growth, Quartararo stated, “Our focus is on autonomous systems rather than Advanced Air Mobility, given the regulatory challenges tied to AAM. Our primary markets consist of defense segments (ISR, UAVs, UGVs, USVs), as well as monitoring equipment in the energy sector, including offshore wind farms, oil and gas inspections, and uncrewed surface vehicles.”

“The uncrewed surface vehicle field is currently thriving due to both commercial operations like energy and surveying as well as defense autonomy initiatives shaped by geopolitical factors. Numerous surface vehicle operators are implementing shallow-submerged, pressure-compensated actuators derived from our subsea technologies.”

Quartararo remarked, “Our dual-redundant L-Series actuator is groundbreaking, being one of the few redundant linear actuators available outside of highly specialized markets. Additionally, we manufacture all components in the U.S., ensuring direct customer support, in contrast to many suppliers reliant on distributor networks. Our commitment is to high-quality, CNC-machined components, with no compromises on reliability.