Why NASA Wants Turbine Air Motors: An Expert Dive

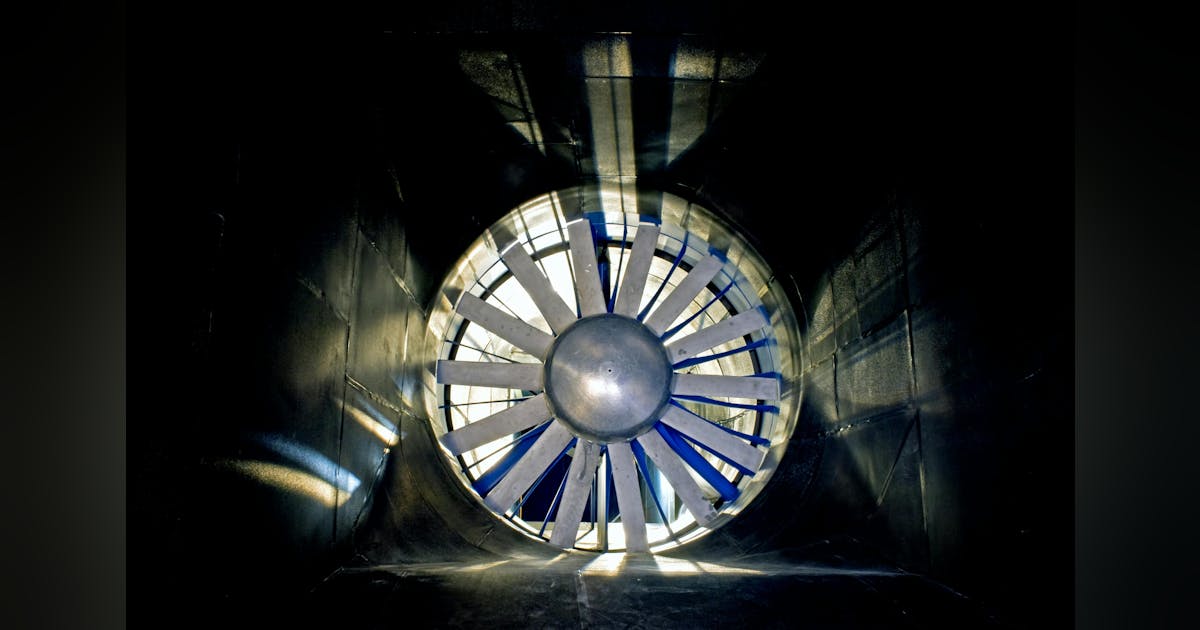

In the realm of aviation, designers consistently challenge the boundaries of materials, aerodynamics, and propulsion systems. To accurately predict the performance of future planes, particularly those with revolutionary engine designs or propfan concepts, NASA extensively utilizes wind tunnel experiments. These tests are critically supported by turbine air motors, which are sophisticated devices capable of recreating the complex airflow and forces expected during actual flight.

Vision & Goals

- Propulsion-airframe integration poses a significant challenge for future aircraft designs such as sustainable aviation, drones, or air taxis. Through its recent acquisition, NASA aims to simulate the interaction of integrated propeller systems with wings and fuselages during cruise speeds. This will unlock vital data necessary for the development of next-generation designs.

Technical Requirements at a Glance

NASA’s request for turbine air motors isn’t for standard equipment. Key features include:

| Requirement | Description |

|---|---|

| Number of Units | Four (two primary, two backup) |

| RPM | Up to 20,000 |

| Power Rating | Up to 170 horsepower |

| Configurability | Supports single and contra-rotating fans |

| Mounting Flexibility | Upright or inverted orientations |

| Test Environment | Isolated and installed testing across facilities |

| Power Sources | Electric, pneumatic, or hydraulic (test-dependent) |

| Size | Compact for wind tunnel integration |

| Reversibility | Motors must be reversible for dynamic testing scenarios |

These motors must be versatile, reliable, and extremely adaptable, functioning across different tunnel setups, and aiding in the evaluation of individual components or fully integrated systems without incurring substantial hardware redesign costs.

Unique Use Case: Propfan Simulation

Unlike standard wind tunnel tests that simply allow air to flow past a static model, emerging propfan engines—such as futuristic open-rotor designs—generate far more intricate airflow patterns. NASA’s turbine air motors are critical for:

- Rotating propellers on a wing-body test model at varying, realistic speeds.

- Enabling measurement of aerodynamic performance under simulated cruising conditions.

- Testing single and contra-rotating configurations, essential for assessing efficiency and noise levels.

While propfans offer significant fuel savings, integrating them with airframes presents aerodynamic and acoustic challenges. These tests allow NASA to meticulously examine these interactions.

Wind Tunnel Testing: Why It Matters

Real-World Flight in a Controlled Setting

NASA’s 11-by-11-foot Unitary Plan Wind Tunnel is renowned for assessing supersonic and transonic aircraft. Engineers can:

- Accurately control variables such as airspeed, pressure, and temperature to replicate flight conditions.

- Mount scaled models, sometimes as small as 1/50th of the actual aircraft, equipped with numerous sensors to measure various dynamic properties.

- Utilize potent systems, like ABB’s 135,000-horsepower synchronous motors, in recreating Mach 1 plus airflow conditions and Reynolds numbers experienced in real flight.

Recent Innovations

Recent upgrades to NASA’s wind tunnel drive systems have enhanced precision and reduced maintenance needs, extending the facilities’ operational lifespan and allowing for more sophisticated testing capabilities.

Cutting-Edge Testing Techniques

- Advanced Optical Measurement: The use of sheet lasers, along with pressure-sensitive and temperature-sensitive paints, allows scientists to visualize airflow and temperature gradients.

- Sensor Arrays: Conducting tests, NASA equips wings and propellers with hundreds of pressure and force sensors, detecting meticulous aerodynamic and acoustic particulars.

- Data Sharing: NASA frequently shares its wind tunnel data with industries, catalyzing innovation in commercial aviation, drones, and air mobility platforms.

NASA’s Push for Agility & Cost-Effectiveness

Instead of building new, custom hardware for each test, NASA advocates for modular, flexible turbine air motors to benefit multiple projects—saving money, accelerating project timelines, and swiftly adapting to novel experiments.

This approach supports:

- Testing various fan or propeller sizes and configurations.

- Quick adaptation to any wind tunnel or research goal.

- Reducing critical aerospace discovery lead times.

Real-World Impact: From Airliners to Drones

The insights and technologies derived from these tests significantly influence:

- Ultra-efficient airliners: Enhancing integration between advanced engines and airframes, leading to lower fuel consumption.

- Urban Air Mobility (UAM): Facilitating electric air taxi development, where compact propulsion integration is crucial.

- Drones & UAVs: Optimizing propeller systems for quieter, more effective flight, essential for delivery drones, surveillance, and emergency response missions.

Expert Insights: What’s Next?

“It’s not just about spinning a propeller,” a NASA test director explains. “We must understand how the propeller, wing, and airframe influence each other. Every increment of improvement in efficiency or noise reduction is significant. With these turbine air motors, we can mimic operational conditions, explore innovative designs, and predict full-scale performance before taking flight.”

NASA’s findings permeate the aerospace sector—engine companies employ the data to create quieter, greener turbines; aircraft manufacturers reshape wing-body geometries; and drone innovators achieve enhanced performance efficiency.

Case Study: ABB’s Motor Drive Upgrade

In one of NASA’s wind tunnels, ABB upgraded an outdated drive system with a 101 MW variable-speed drive, capable of operating a colossal 135,000-hp fan. This milestone setup allows Mach 1 airflow, grants remarkable control while reducing maintenance needs, and fulfills NASA’s objective of maintaining specialized and effective test infrastructures as the aviation landscape continues evolving.

The Broader Picture: NASA’s Wind Tunnel Network

NASA operates several leading wind tunnels:

- Ames 11×11 UPWT (evaluating supersonic and transonic flow, currently awaiting the new turbine air motors).

- Langley NTF (a cryogenic tunnel producing ultra-high Reynolds numbers, recently enhanced by ABB).

- Glenn 9×15 (the country’s busiest low-speed propulsion acoustic tunnel).

Each facility facilitates unique research efforts, from hypersonic vehicles to vertical take-off aircraft and electric drones.

How Industry Can Participate

NASA’s current proposal request is now open, inviting engineers and manufacturers proficient in high-performance air motors to submit their proposals. It’s a rare opportunity to influence tomorrow’s plane engines or even spacecraft.

– Deadline for proposals: September 5, 2025

– Proposals need to meet demanding technical criteria for reliability, speed, and configurability.

For Students & Enthusiasts: Why Should You Care?

Wind tunnels are more than cold, cacophonous chambers; they’re *innovation crucibles* for aerospace. Each new generation of quieter, more efficient aircraft owes its success to these crucial tests. Next time you hear a drone in your neighborhood or land on a fuel-efficient airliner, remember that NASA and its partners have tirelessly experimented in tunnels, measuring forces that escape the unaided eye.

NASA’s Promise: Data for All

After acquiring data with these new air motors, NASA will assess and publish its findings online, offering impetus for progress throughout the aerospace industry. Whether you’re a seasoned engineer, an aspiring drone enthusiast, or a student with dreams of Mars, the innovations taking shape today result from the wind tunnel endeavors ongoing now.

In summary: NASA’s pursuit of turbine air motors is a crucial initiative for comprehending and advancing propulsion-airframe integration for future aircraft and drones. With these versatile, high-performance motors, researchers can emulate realistic flight conditions, harvest crucial data, and pave the way for the future of aviation and air mobility.