Design and Development Tools for Seamless Software Integration in Life Sciences: Emerson’s Strategy

Amidst the rapid advancements in life sciences, where cutting-edge therapies and personalized medicines are revolutionizing healthcare, seamless data integration has become vital. Emerson, a leader in industrial automation technology, launches a range of design and development tools aimed at revolutionizing software component connectivity, fostering collaboration, and driving innovation throughout the life sciences value chain.

Let’s explore how Emerson’s robust solutions are transforming life sciences organizations—and how your team can leverage these tools to enhance efficiency, ensure compliance, and accelerate market entry.

The Challenge: Bridging Fragmented Data and Manual Processes

Consider the journey of transforming promising research into full-scale commercial manufacturing: a marathon fraught with obstacles like fragmented data, error-prone manual processes, and isolated software tools. Connectivity breakdowns delay therapies, increasing risks and hindering patient access.

Emerson’s mission is to dismantle these barriers, ensuring all operations are seamlessly connected from the lab bench to the patient bedside.

Emerson’s DeltaV Automation Platform: Integration at Its Core

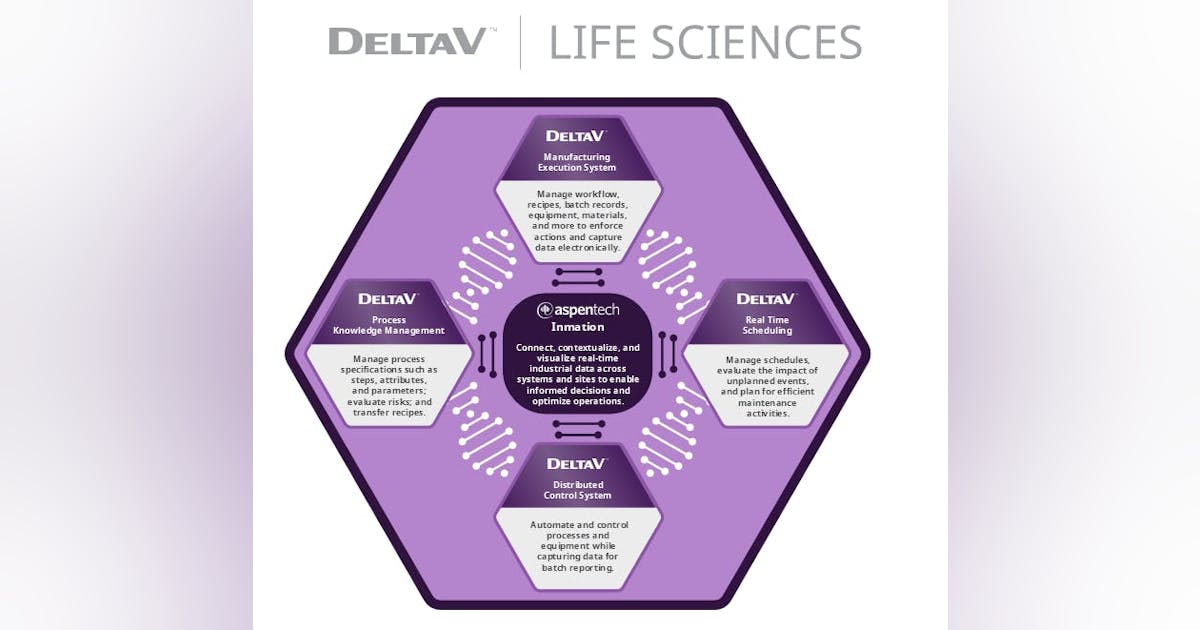

Emerson’s DeltaV Automation Platform is central to meeting the life sciences industry’s demands.

Key Features and Benefits

- Unified Software Suite: Integrates process control (DCS), manufacturing execution (MES), process management (PKM), and real-time scheduling.

- Common Data Fabric: Employs Emerson’s AspenTech Inmation™ for streamlined, context-rich data flow across the value chain.

- Reduced Customization: Standardized connectivity minimizes custom integrations, easing scale-up and tech transfer.

- End-to-End Support: Supports every stage from early research to full-scale manufacturing, eliminating disconnected software islands.

- Collaborative Environment: Facilitates information sharing, overcoming the silos affecting drug development and manufacturing.

Inside the Software Suite: Modular and Interoperable

Emerson’s architecture is a set of interoperable, modular tools—not a one-solution-fits-all.

| Tool | Purpose | How It Connects |

|---|---|---|

| DeltaV DCS | Core process automation and control | Direct data feed into suite |

| DeltaV MES (Syncade) | Manufacturing execution, batch management | Tight integration with PKM |

| DeltaV PKM | Process & knowledge management for easy tech transfer | Seamlessly shares recipes |

| DeltaV Real Time Scheduling | Optimizes production timing and flow | Uses real-time plant data |

| AspenTech Inmation™ | Real-time unified data platform | Common data hub for all |

These components empower teams with detailed insights from recipe creation to real-time production metrics within one digital environment.

Real-World Outcomes: Success Stories

Emerson’s tools are already driving success across global life sciences and chemical industries.

Streamlining Digital Advancement: A European chemical firm revitalized its legacy control system using Emerson’s DeltaV technologies, boosting compliance and future-proofing its architecture for Industry 4.0.

Drug Development Acceleration: Another client used PKM and MES for simplified tech transfer, reducing the development cycle from over a decade to under three years, benefiting patients and revenue.

Expert Insights: Significance of Integration

Michelle Adkins, Emerson’s Director of Life Sciences Strategy, and Karen Fung, Senior Engineering Manager, affirm that digitalization is key to:

- Speeding clinical trials

- Reducing patient costs

- Enhancing inventory management

- Strengthening supply chains

- Supporting adaptable manufacturing

“Integration is crucial for accelerating life sciences outcomes across pipeline, manufacturing, operations, real-time release, and sustainable practices.”

Technical Insights: The Functional Process

From Lab to Launch: Scientists log data into PKM for a digital record, forwarding parameters to MES for consistent batch fidelity, with DCS and analytics overseeing real-time changes and compliance reporting.

Automation Blocks: Emerson’s modular blocks allow process adaptation, significantly beneficial for personalized medicine or evolving projects.

Future Trends and Opportunities

The digitalization journey is evolving, with Emerson focusing on:

- Total Automation: Enhancing data mobility from molecular discovery to delivery

- Digital Twins: Running virtual models for risk-free testing and process improvement

- AI and Real-Time Insights: Utilizing AspenTech Inmation™ for predictive insights

- Interoperability: Expanding MTP standards for multi-vendor DCS and PLC integration

Emerson’s Collaborative Approach

At Emerson, expertise meets collaboration. Their domain knowledge combines with client partnership, facilitating a smooth transition from blueprint to optimized implementation.

Initiating with Emerson’s Life Sciences Suite: Practical Steps

- Identify your data bottlenecks.

- Engage Emerson’s consultancy services.

- Begin modular automation pilots.

- Prioritize seamless tool integration.

- Invest in team training for accelerated digital adoption.

Culture and Future Outlook

If managing your lab’s data feels like “herding cats,” Emerson’s solutions offer a streamlined approach, transforming chaos into an expertly coordinated system, much like an advanced digital suit for your facilities.

Fun Fact: The DeltaV platform enjoys meme status among engineers, humorously equated with teleportation for its data integration efficiency.

Conclusion: Pioneering a Connected Future in Life Sciences

Emerson’s design tools offer unmatched solutions to connect software, automate processes, and expedite new therapies to market. Leveraging the DeltaV Automation Platform, you’re investing in technology that supports teams, enhances compliance, and speeds patient recovery worldwide.

Interested in more insights or a demo? Visit Emerson Exchange events, engage in their digital forums, or contact their specialists. The era of connected, data-driven life sciences is here, guided by Emerson.

Emerson: Leading in automation innovation for a promising health future.